- Home

- /

- Flame Retardant Tape

Flame Retardant Tape

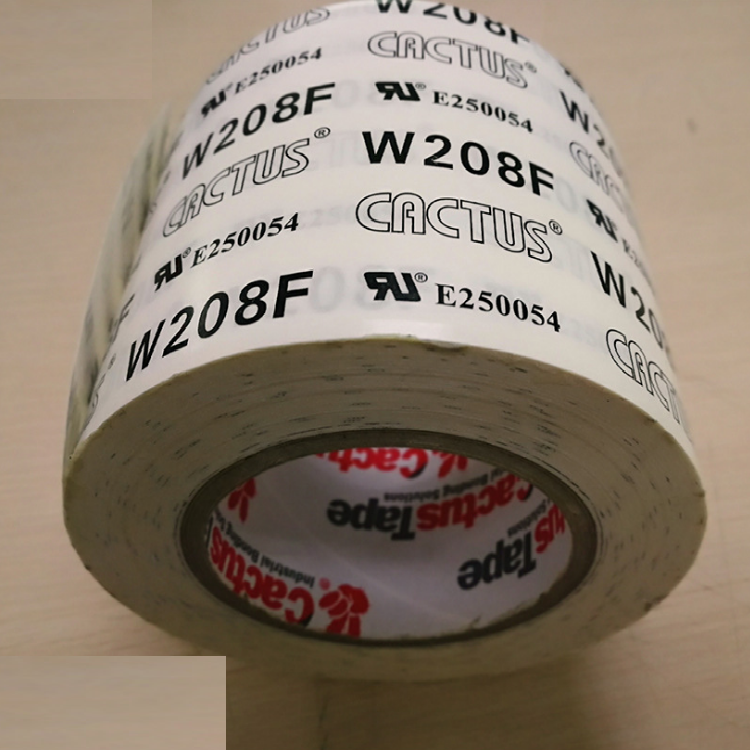

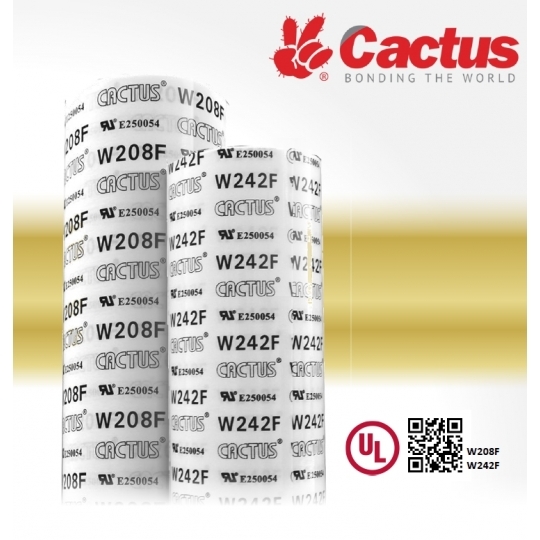

W208F

Carrier

None (Unsupported transfer tape)

Adhesive

Acrylic solvent-based adhesive offering exceptional resistance to high temperatures, chemicals, and water permeation. It is flame retardant and halogen-free, meeting UL 94 V0 standards (File No. E250054). Source

Liner

White paper liner

Tape Thickness

2.4 mils (0.06 mm)

Tape Color

White

Liner Color

White

W242F

Carrier

Double-coated tissue carrier that ensures stability and strength during application.

Adhesive

Acrylic-based adhesive offering strong initial tack and excellent adhesion to a wide variety of substrates. It provides long-term bonding, ensuring reliable performance in demanding environments.

Liner

White paper liner with excellent release properties, designed to facilitate easy handling and application.

Tape Thickness

5.0 mils (0.127 mm)

Tape Color

White

Liner Color

White

W292F

Carrier

Film

Adhesive

Acrylic-based adhesive offering strong initial tack and excellent adhesion to a wide variety of substrates. It provides long-term bonding, ensuring reliable performance in demanding environments.

Liner

White paper liner with excellent release properties, designed to facilitate easy handling and application.

Tape Thickness

4.3 mils (0.11 mm)

Tape Color

White

Liner Color

White

W2010

Carrier

Transfer

Adhesive

Acrylic-based adhesive offering strong initial tack and excellent adhesion to a wide variety of substrates. It provides long-term bonding, ensuring reliable performance in demanding environments.

Liner

White paper liner with excellent release properties, designed to facilitate easy handling and application.

Tape Color

Clear

Liner Color

White

What Is Flame Retardant Tape?

Flame retardant tape serves an essential role in enhancing safety across various industries by minimizing the risk of fire spread. Composed of advanced materials, often including phosphoric acid esters, it not only provides strong adhesion and insulation but also meets stringent safety standards like UL 94. With applications in construction, automotive, and electrical sectors, this tape offers vital flame resistance and mechanical reinforcement, ensuring protection. What makes these tapes indispensable in modern safety protocols?

Understanding Flame Retardant Tape

Flame retardant tape, while often overlooked, plays an essential role in meeting stringent fire propagation and survival requirements. Its applications overview reveals its versatility across construction, automotive, electrical, and industrial sectors, providing critical safety in public, enclosed, and underground spaces. This tape excels in wrapping, bonding, and insulating, ensuring protection and compliance with fire safety standards.

The manufacturing process is vital to its effectiveness, focusing on creating durable, environmentally safe tapes free from harmful substances. This involves precise lamination techniques to produce various types, such as thin double-sided and polyethylene-coated tapes. Each type’s manufacturing is tailored to meet specific regulatory standards, ensuring they serve as reliable fire barriers while maintaining structural integrity and environmental safety in emergency situations.

Key Testing Methods for Flame Retardant Tapes

1. FAR 25.853 – Aircraft Materials Flammability Test

- Purpose: Required by the FAA for materials used in aircraft interiors.

- Tests Include:

- Vertical burn (60-second & 12-second versions): Measures flame time and burn length.

- Horizontal burn: Used for floor-level materials.

- Heat release and smoke density: For materials in seating and panels.

- Application: Crucial for tapes used in aircraft cabin interiors, wiring insulation, or structural bonding.

2. UL 94 – Flammability of Plastic Materials

- Vertical (V-0, V-1, V-2) and Horizontal (HB) burning classifications.

- Application: Common in electronics, appliance tapes, and industrial usage.

3. FMVSS 302 – Automotive Interior Materials

- Purpose: Measures horizontal burn rate.

- Requirement: ≤ 102 mm/min burn rate.

- Application: Automotive tapes used in dashboards, seats, wire harnesses.

Diverse Applications of Flame Retardant Tape

With the understanding of key materials and compositions established, attention turns to the myriad applications of flame retardant tape in safety-critical fields. In automotive and transportation, these tapes bond, insulate, and protect components, conforming to industry standards like FAR 25.853(a) for aviation. They’re essential in shipbuilding and other transportation sectors to comply with fire safety regulations. In construction, flame retardant tapes provide protection by wrapping, bonding, and sealing, especially in high-risk environments. Industrial applications focus on safeguarding combustibles, while electrical and HVAC sectors utilize these tapes for insulation and sealing. Public safety demands non-hazardous tapes for use in auditoriums and convention centers. These innovative applications reflect current market trends prioritizing compliance and fire prevention.

Advantages and Features of Flame Retardant Tape

Although flame retardant tape is a versatile tool, its true value lies in its distinct advantages and features, particularly in safety-critical applications. The tape’s high flame resistance and excellent self-extinguishing properties are essential performance features that prevent fire propagation and enhance safety. Its thermal insulation capabilities protect components from external heat sources, effectively reducing thermal runaway risks. The mechanical reinforcement provided by the tape enhances structural integrity, guaranteeing long-term application advantages in demanding environments. Additionally, the high-performance adhesive properties secure attachment, imperative for maintaining reliability. Its role as an early warning system allows for safer evacuation by delaying flame spread. Together, these features assure consumers of proactive safety measures, encouraging wider adoption in industries like electric vehicles.

Different Types and Variants of Flame Retardant Tape

Flame retardant tapes come in various types, each designed to meet specific performance needs in environments where fire safety is critical. Flame retardant transfer tapes offer maximum adhesive coverage without a carrier, making them ideal for bonding irregular or flexible substrates while maintaining flame-resistant performance. Flame retardant double-sided film tapes feature a plastic film carrier that provides both electrical insulation and thermal conductivity, making them suitable for electronics or thermal management applications. Double-sided tissue tapes offer enhanced conformability, allowing them to easily adapt to textured or uneven surfaces while still delivering flame retardant protection. Lastly, flame retardant fiberglass tapes combine a high-temperature-resistant fiberglass carrier with strong adhesives to deliver excellent electrical insulation and thermal conductivity, especially in high-heat or high-voltage applications like cable wrapping or electrical component assembly. Each type addresses unique functional and safety requirements across industries such as aerospace, automotive, and electronics.

Choosing the Right Flame Retardant Tape

When selecting the right flame retardant tape, how can one assure maximum fire safety and performance? Confirming compliance with fire safety standards like UL94 or FMVSS 302 is fundamental. Application considerations include material compatibility to guarantee proper adhesion and environmental resistance to withstand temperature extremes, moisture, UV exposure, and chemicals. Adhesive strength must meet the demands of either permanent or temporary bonds, assuring effective performance across different surface types. Performance features such as self-extinguishing properties and low smoke emission are essential. Tape maintenance involves selecting options that resist degradation over time and offer easy removal with minimal residue. Additionally, choosing halogen-free options is significant for industries sensitive to toxic emissions, assuring both safety and durability.

Frequently Asked Questions

How Long Does Flame Retardant Tape Last After Application?

The application lifespan and effectiveness duration of flame retardant tape depend on factors like environmental conditions, temperature, and surface preparation. Typically, it lasts 12-24 months when applied correctly and maintained under recommended storage and usage conditions.

Can Flame Retardant Tape Be Used Outdoors?

Flame retardant tape’s properties make it ideal for outdoor applications where fire safety is critical. Its high conformability and weather-resistance guarantee reliable performance in mechanical and electrical settings, providing secure seals and insulation in varying conditions.

Are There Any Specific Storage Conditions for Flame Retardant Tape?

Flame retardant tape’s storage requirements include keeping it at room temperature, away from heat, sunlight, and moisture. Maintaining humidity control is crucial for its shelf life, ensuring it remains effective and safe for use over time.

Is Flame Retardant Tape Eco-Friendly and Recyclable?

Flame retardant tape can be eco-friendly, made from eco-friendly materials like cotton paper. However, its recyclability depends on the recycling process and materials used. Checking local recycling policies guarantees alignment with environmental and safety standards.

What Is the Temperature Range for Effective Use of Flame Retardant Tape?

Application methods depend on specific needs: aerospace, electronics, or industrial, ensuring safety and performance in high-temperature environments.